Adaptability is also known as compatibility, if the admixture is added to the cement that meets the national requirements, the expected use effect can be obtained, it means that the cement and the admixture are compatible, otherwise it means that the cement and the admixture are not adaptable. For example, through the rational application of superplasticizers, the fluidity of cement can be improved under the same amount of water, and the unilateral water consumption of concrete can be effectively reduced. If analyzed in a broad sense, adaptability can also understand the fluidity, setting time and strength changes of cement slurry.

1. Influencing factors

1.1 Mineral composition

The main factor is the content of C3A and C4AF, if the content of these components is relatively low, the adaptability of cement and superplasticizer will be relatively good, and the influence of C3A on adaptability is relatively strong. This is mainly due to the fact that the superplasticizer first adsorbs C3A and C4AF. In addition, the hydration rate of C3A is stronger than that of C4AF and increases with the increase of cement fineness. If the cement contains more C3A, it will directly lead to a relatively small amount of water dissolved in sulfate, resulting in a smaller amount of sulfate ions.

1.2 Fineness

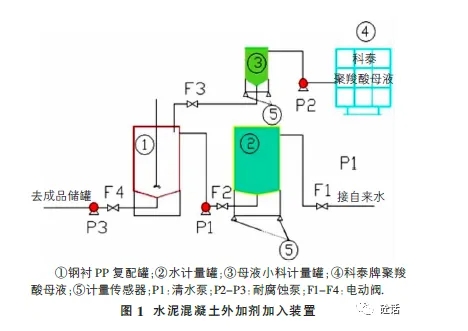

If the cement is finer, its specific surface area will be relatively large, and the flocculation will become more obvious. In order to avoid this flocculation structure, a certain amount of superplasticizer needs to be added to it. In order to obtain sufficient flow effect, it is necessary to increase the use of superplasticizer to a certain extent. Under normal circumstances, if the cement is finer and the specific surface area of the cement is relatively high, the influence of the superplasticizer on the saturation content of the cement will increase, and it is difficult to ensure the fluidity of the cement slurry. Therefore, in the actual configuration of concrete with high water-cement ratio, it is necessary to carefully control the water specific area to ensure that the cement and superplasticizer have strong adaptability [1]. (Figure 1)

1.3 Grading of cement particles

The influence of cement particle grade on cement adaptability is mainly reflected in the difference of fine powder content in cement particles, especially the content of particles less than 3 microns, which has the most direct influence on the adsorbability of water reducer. The content of particles smaller than 3 microns in cement varies greatly depending on the cement manufacturer, usually ranging from 8 to 18%. After the use of open-flow grinding system, the specific surface area of cement has been greatly improved, which has the most direct impact on the adaptability of cement and water reducer.

1.4 Roundness of cement particles

There are many ways to improve the roundness of cement. In the past, cement particles are usually used to avoid grinding away the edges, but in the actual operation process, a large number of fine powder particles are prone to appear, which has a very direct impact on the performance of cement. In order to effectively solve this problem, the circular steel ball milling technology can be directly used, which can greatly improve the degree of spherodization of cement particles, reduce operating losses, and shorten the cement grinding time. After the roundness of the cement particles is increased, although the impact on the saturated content of water reducer is not very large, it can improve the initial flow of the cement slurry to a large extent, and this phenomenon will be more obvious when the use of water reducer is small. In addition, after improving the roundness of cement particles, the fluidity of cement slurry can also be improved to a certain extent.

1.5 Mixed Materials

At present, in the process of cement use in China, it often appears that other materials are used together. These mixtures usually include blast furnace slag, fly ash, coal gangue, zeolite powder, limestone, etc. After a lot of practice has proved that if the use of water-reducing agent and fly ash as a mixed material, can get a relatively good adaptability of cement. If volcanic ash and coal gangue are used as mixing materials, it is difficult to get a better mixing adaptability. In order to get a better water reducing effect, more water reducing agents need to be used. If fly ash or zeolite is included in the mixed material, there is usually a very direct relationship between the firing loss and the fine volcanic ash, the less the firing loss, the relatively large amount of water is required, and the higher the volcanic ash. After a lot of practice has proved that the adaptability of the mixed material to cement and water reducing agent is mainly reflected in the following aspects: (1) If the slag is used to replace the cement slurry, the stronger the liquidity of the slurry disposal will be with the increase of the replacement rate. If fly ash is used directly to replace the cement slurry, its initial fluidity can be reduced to a great extent after the replacement material exceeds 30%. (3) If zeolite is used directly to replace cement, it is easy to lead to the occurrence of initial insufficient liquidity of the slurry. Under normal circumstances, with the increase of slag substitution rate, the flow retention of cement slurry will be enhanced. With the increase of fly ash, the flow loss rate of slurry will increase to a certain extent. When the replacement rate of zeolite exceeds 15%, the slurry flow loss will be very obvious.

1.6 Influence of admixture types on fluidity of cement paste

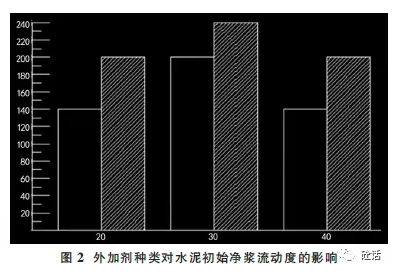

In the actual test process, the direct use of Jiangsu Bote Co., Ltd. production of naphthalene admixtures and polyhydroxyacid high-performance admixtures. The effect of admixtures on cement fluidity is shown in Figure 2. It can be seen from the analysis of FIG. 2 that without considering the effect of external factors, whether the cement is ground for 20 minutes or 30 minutes, the use effect of admixture 2 is obviously better than that of admixture 1. By adding a certain proportion of admixtures into concrete, the water-repellent groups of admixtures will be directively adsorbed on the surface of cement particles, and the hydrophilic groups will point to the solution, thus effectively forming an adsorption film. Due to the directional adsorption effect of the admixture, the surface of the cement colloidal particles will carry the same symbolic charge, and under the action of the same sex repulsion, the cement forms a dispersion of flocculation-like structure in the initial stage of adding water, so that the flocculation-like structure can be released from the water, thereby improving the flow of the water body to a certain extent. Compared with other admixtures, one of the main characteristics of polyhydroxyl acid admixtures is that they can form groups with different functions on the main chain. Under normal circumstances, hydroxyl acid admixtures will have a greater impact on the fluidity of cement. In the preparation process of high-strength concrete, adding a certain proportion of polyhydroxyl acid admixtures can play a better preparation effect. However, in the process of using polyhydroxic acid admixtures, it has relatively high requirements for the performance of cement raw materials. In the actual use process, it is easy to appear the phenomenon of thick and sticky mixture, and the phenomenon of bleeding and delamination in the later use process of the building, and it is also easy to appear the phenomenon of pockmarked surface, sand line and porosity after mold removal. This is directly related to the incompatibility factors of polyhydroxyacid admixtures with cement and mineral admixtures. Polyhydroxyacid admixtures have the worst adaptability with cement among all kinds of admixtures. The influence of admixtures on the initial flow of cement clean paste is shown in Figure 2.

1.7 Influence of stirring time and stirring speed

The length of mixing time has relatively direct influence on the concrete content and the dispersion effect of concrete admixtures, and indirectly affects the workability, mechanical properties and durability of concrete. If the mixer runs too fast, it is easy to damage the colloidal structure of the cement and the double electric layer film on the surface of the cement particles, and eventually lead to the concrete setting time and collapse are greatly affected, and the mixing speed needs to be controlled at 1.5-3 minutes. If the dry blending method is adopted, the effect of dressing the concrete can be ensured by using the water reducing agent reasonably. If it is necessary to use a solution for mixing, water needs to be deducted from the mixing during the configuration of water reducer, so as to ensure that the water-cement ratio design is reasonable. In order to ensure the slump of concrete and give full play to the role of water reducing agent, the post-mixing method can be directly used. Different from the addition method of high efficiency superplasticizer, reasonable use of the post-mixing method can ensure the ease and consistency of concrete. If it is necessary to use a mixing truck to transport concrete, the water-reducing agent can be added to the mixing truck 2 minutes before unloading to reasonably increase the mixing speed of the mixing truck and improve the discharge effect.

1.8 Impact of ambient temperature and humidity

The setting time, hardening rate and early strength of concrete mix have a very direct relationship with the curing temperature, after adding water reducing agent, this phenomenon is more obvious, and the effect of setting time below 20 degrees Celsius will be more significant. Under normal circumstances, the higher the temperature, the faster the hydration rate of cement, the faster the evaporation rate of the concrete surface will be faster and faster, the free water inside the concrete will continue to replenish the surface of the concrete through the capillary, further accelerate the hydration effect of cement, the free water in the concrete is evaporated and reduced, thereby further causing the loss of concrete slump. In addition, the retarding effect of some concrete admixtures will be greatly reduced above 30 degrees Celsius. Therefore, if you need to work in a high temperature environment, it is necessary to increase the amount of concrete admixtures reasonably, so as to effectively avoid the occurrence of water evaporation. Wood calcium has a certain retarding property, after pouring for a long time, in order to have a certain structural strength, in the maintenance process, it is necessary to extend enough static time, and scientific design of the dosage, otherwise the concrete in the use of the process, prone to more serious cracks, surface loose, drum phenomenon. In the process of using high efficiency water reducer, due to the relatively low gas intake, the retarding effect can not be guaranteed, and too long static stop time is not required in the process of steaming. Therefore, in the process of adding admixtures, the related maintenance work should be carefully done to avoid serious water evaporation in the maintenance process.

1.9 Cement storage time

Under normal circumstances, the shorter the storage time of cement, the fresher it will appear, and the worse the plasticizing effect of cement will be. The fresher the cement will be more positive, and the number of ionic surfactants adsorbed will be more, for newly processed cement, its water reduction rate is lower and slump loss is faster. For cement with a long storage time, these problems can be avoided.

1.10 Alkali content in cement

The amount of alkali content also has a very direct impact on the adaptability of cement and water reducer. With the increase of cement alkali content, the plasticizing effect of cement will become worse, after the alkali content exceeds a certain range, it will also have a very serious impact on the setting time and slump of cement. In addition, the form of alkali in cement also has a very direct impact on the use of water reducer. Under normal circumstances, if the base is present in the form of sulfate, its effect on the water reducer is less than the presence of hydroxide form.

1.11 Plaster in cement

By adding cement gypsum to cement, the hydration of cement can be delayed to a large extent, avoiding the direct adsorption of cement and water reducing agent, so as to effectively improve the adaptability of cement and water reducing agent. According to a large number of studies, the adsorption amount of water-reducing agent on cement mineral C3A can be effectively reduced after adding a certain amount of gypsum to cement, mainly because gypsum and C3A can react and generate ettringite, which will directly cover the surface of C3A and avoid further hydration of C3A. This can greatly reduce the adsorption of C3A particles on water reducer. The dissolution rate and solubility of different kinds of gypsum are very different. The type and content of cement gypsum have a direct effect on the adaptability between cement and water reducing agent. The pore liquid sulfate in cement concrete mainly comes from the sulfate formed by Portland cement, which will have a very direct impact on the hydration reaction of cement and the workability of Portland cement concrete. The sulfate ions in gypsum often undergo different changes during the grinding process. If the temperature of the grinding process is high, the dihydrate gypsum will partially dehydrate and form a semi-hydrate gypsum. If the internal temperature of the mill is too high, a large amount of semi-aqueous gypsum will be formed in this process, and eventually lead to the occurrence of cement false setting. For the cement containing relatively less alkaline sulfate, under the strong adsorption of sulfonic acid-containing superplasticizer, it will directly lead to a very fast decline in concrete collapse, and when the soluble sulfate content increases, the adsorption of highly efficient superplasticizer will become a quasi-linear decline trend.

1.12 Cement grinding aid

The effect of cement grinding can be greatly improved by reasonable use of cement grinding AIDS. In the process of cement production in many foreign cement enterprises, grinding AIDS are often used in large quantities. In recent years, after the implementation of new cement standards in China, the strength and fineness requirements of cement have been improved, which puts higher requirements on the use of grinding AIDS. At present, there are many kinds of cement grinding AIDS, and the number of grinding aid manufacturers in China also shows an increasing trend. Various cement grinding aid manufacturers in the development of economic, efficient, easy to use grinding aid process, continue to invest strength. However, some grinding aid manufacturers pay too much attention to the production cost, and invest relatively little power in the research of the performance of grinding AIDS, which has a very bad effect on its use: ① The use of substances containing halogen salts is easy to lead to the occurrence of steel corrosion inside the concrete. ② The use of too much lignin sulfonate leads to the incompatibility of cement and concrete admixtures is relatively serious. In order to effectively reduce production costs, there is often a large amount of industrial waste, which has a very bad impact on the durability of concrete. In the current concrete production process, the content of alkali and chloride ions, the types of gypsum and clinker minerals have a very direct effect on the distribution of cement particles. The durability of the cement cannot be sacrificed during the use of the grinding aid. The composition of grinding aid is relatively complex. Only reasonable use of grinding aid can ensure the use effect of concrete. In the production process, the grinding process of the enterprise should be fully understood, and the type of grinding aid and cement particle grading should be mastered.

1.13 Construction mix ratio

Construction mix ratio is an engineering design problem, but it has a very direct impact on the adaptability of concrete admixtures and cement. According to the relevant data, if the sand rate is too high, it is easy to lead to the phenomenon of reducing the fluidity of the concrete mix, and the slump loss is very large. In addition, the stone shape, water absorption and grading in the concrete mix ratio will also affect the constructability, water retention, cohesiveness, fluidity and formability of concrete to a certain extent. The relevant experiments show that the strength of concrete can be improved to a certain extent by reducing the water-cement ratio. In the case of optimal water consumption, the performance of cement concrete can be fully brought into play, so that its plasticity can be fully improved, the concentration of admixtures can be ensured, and the adaptability of admixtures and cement can be improved.

1.14 Influence of other factors

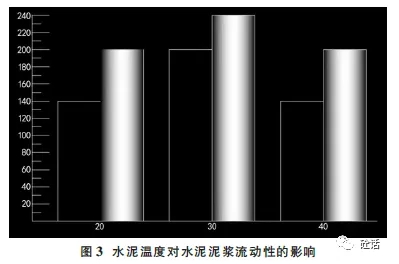

Factors such as admixture itself, cement variety, cement temperature (the influence of cement temperature on cement slurry fluidity is shown in Figure 3) are also important factors affecting the adaptability of cement and admixtures. Different raw material manufacturers have relatively large differences in raw material selection and production process control. In order to obtain the adaptability of cement and admixtures, it is necessary to do a good job of relevant investigations and grasp the actual situation of the current cement market. If conditions permit, we should also carefully do a good job of cement-related performance testing, master the composition and proportion of cement, and seriously carry out relevant adaptability tests, try to buy cement products produced by large manufacturers, and choose cement varieties according to the actual situation of the project, to avoid improper selection of cement, which has a serious impact on the quality of the project.

2 Conclusion

With the continuous development of The Times, the use of cement concrete has put forward higher requirements. The adaptability of cement and admixture has a very direct influence on the performance of cement. In order to ensure the adaptability between cement and admixtures, it is necessary to master the various factors affecting the adaptability, and then fully do the adaptability test work to avoid the flow of products with insufficient adaptability into the construction of the project, and further ensure the construction quality of the project.

Source: Network, if it involves the content of the work, copyright and other issues, please contact us promptly, we will deal with as soon as possible.